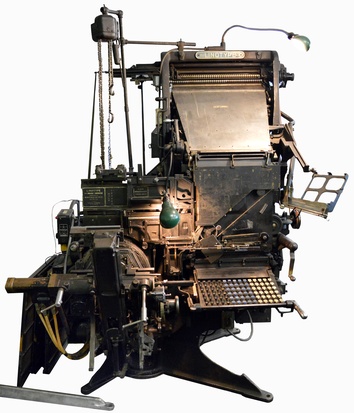

Linotype Model 31

- Date Acquired :

- 2006

- Designer :

- Ottmar Mergenthaler (1854-1899)

- Year :

- 1948

- Source :

- John and Robert Bove

Ottmar Mergenthaler (1854-1899) invented the Linotype Baltimore in 1886. With over 36,000 parts, this ingenious machine produces slugs of text that are placed in the letterpress printing press and then printed.

As the Linotype operator types, brass molds called matrices or mats drop down from magazines into the assembly area. Spacers are inserted between words. Once the line is composed, the operator pushes the lever. The line of text is elevated into a mold and molten 535 degrees F metal is injected into the mold. Seconds later, the mold rotates 270 degrees, the slug is trimmed and ejected from the machine. Then the mats and spaces are picked up and automatically sorted back into the proper position for reuse.

This machine, built in 1948, was used at Union Press in Wilmington, Delaware, until August 2006. John and Robert Bove donated the Linotype to System Source.